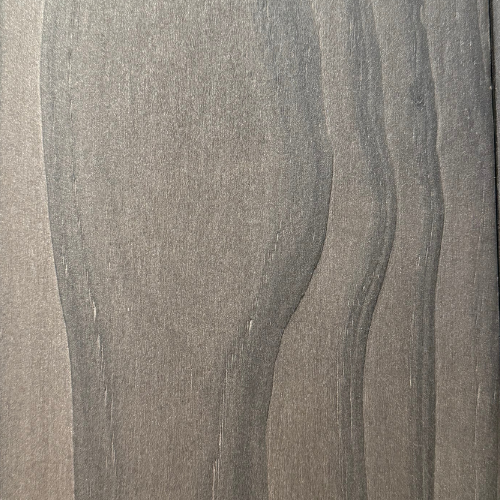

Flatsawn

Flatsawn by texel wood is crafted from ABODO’s thermally modified timber, ensuring exceptional stability in all weather conditions.

The beautiful flat sawn grain runs consistently across the entire cladding board, the wire-brushed finish enhances the wood’s natural beauty and depth.

A carbon negative product, Flatsawn is created from timber sourced from the world’s most sustainable forest and is manufactured and coated in Western Canada.

Sustainable Attributes of Flatsawn ABODO Cladding:

Flatsawn Cladding: Designed for Versatility

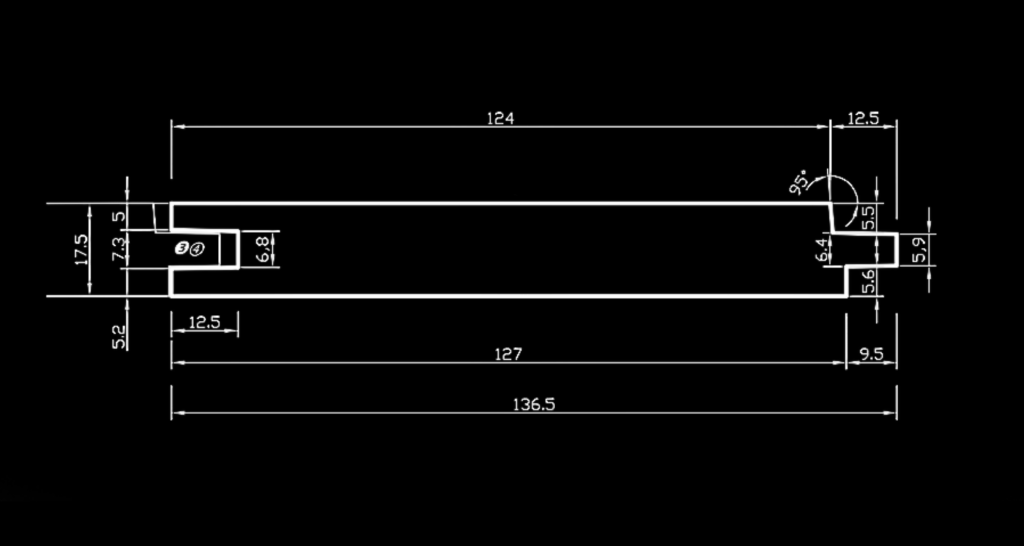

Flatsawn cladding is engineered to provide a versatile solution for any design vision. Its innovative design allows for seamless installation both vertically and horizontally, making it an adaptable choice for a wide range of architectural styles. Whether you’re aiming for a sleek modern look or a classic aesthetic, Flatsawn delivers the flexibility to create the perfect finish for your project.

Click on each colour swatch to see how the colours weather over time.

* Colour variation may occur due to variation in thenatural substrate. Colour may change/fade as part of the weathering process.

Classic Collection:

Benefits of Flatsawn ABODO Cladding:

Yes. For most profiles, we offer various corner, flashing, fascia and finishing profiles to match the cladding boards. Using these accessories will ensure optimal performance of the cladding system in service.

Cladding is bit more technical than decking, so always consult with a professional before starting your project. A Licenced Building Practitioner is required for install.

Abodo cladding may be face fixed or secret fixed depending on the profile shape. Stainless steel ring shank nails or self-drilling stainless steel countersunk screws should be used in all cases. Generally we recommend to fix boards onto a drained cavity system to allow good airflow and optimum weather protection.

All profiles requires a minimum 2mm expansion gap to be left between boards, you need to ensure all cut ends must are resealed with penetrating oil or sealer. Boards should be coated all sides and re-coated regularly as required thereafter.

Refer to the Resources page for more details including installation manual and drawings.